Petroleum Engineering Explained: Contracts, Reservoirs, Drilling, Production & Sustainability

Hello everyone!

We have officially entered the advanced phase of our Petroleum Engineering series. The first 20 sections have already been covered. If you haven’t watched them yet, we highly recommend doing so.

That said, the topics covered here do not strictly depend on prior sections, so you may jump directly to any section using the timestamps provided in the video description.

Understanding Petroleum Contracts and Agreements

The petroleum industry operates through complex legal and commercial agreements involving governments, oil companies, and service providers. Understanding these contracts is essential for navigating the industry.

1. Production Sharing Contracts (PSCs)

Under a PSC, a company explores and produces hydrocarbons on behalf of the government.

- The government retains ownership of resources

- Production is shared between the company and the state

- Common in developing countries

2. Joint Operating Agreements (JOAs)

JOAs allow multiple companies to jointly explore and produce hydrocarbons.

- Risks and rewards are shared

- Roles, liabilities, and responsibilities are clearly defined

3. Concession Agreements

Here, the government grants exclusive rights to a company to explore and produce oil and gas.

- The company pays royalties and taxes

- Ownership of produced hydrocarbons usually belongs to the company

4. Service Contracts

Service companies provide drilling, seismic, or technical services.

- Paid a fixed fee

- No ownership in oil or gas production

5. Farm-Out Agreements

One company (farmer) transfers part or all of its rights to another (farmee).

- Used to reduce risk or raise capital

Conclusion:

Each contract type serves a different commercial and risk strategy. Legal and financial consultation is essential before entering any agreement.

Petroleum Geomechanics and Rock Mechanics

Petroleum geomechanics studies how rocks behave under stress and pressure, which is critical for safe drilling and production.

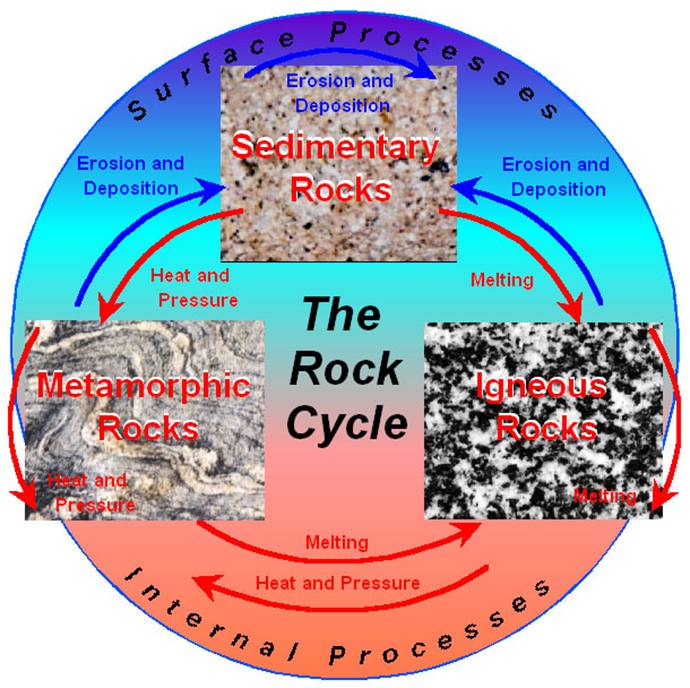

Types of Rocks

- Sedimentary: Main source of hydrocarbons

- Igneous: Formed from magma

- Metamorphic: Altered by heat and pressure

Rock Properties

- Porosity: Space between grains

- Permeability: Ability to transmit fluids

Types of Stress

- Compressive

- Tensile

- Shear

Measurement Methods

- Core analysis

- Well logging

- Seismic imaging

Conclusion:

Understanding rock behavior helps prevent well failure and ensures efficient operations.

Basics of Reservoir Engineering and Management

Reservoir engineering focuses on maximizing hydrocarbon recovery while minimizing cost and environmental impact.

Key Components

- Reservoir properties (pressure, saturation, permeability)

- Reservoir simulation and modeling

- Production monitoring and optimization

- Enhanced Oil Recovery (EOR) methods

Economic Evaluation

- Net Present Value (NPV)

- Return on Investment (ROI)

- Production forecasting

Conclusion:

Effective reservoir management is critical for long-term field success.

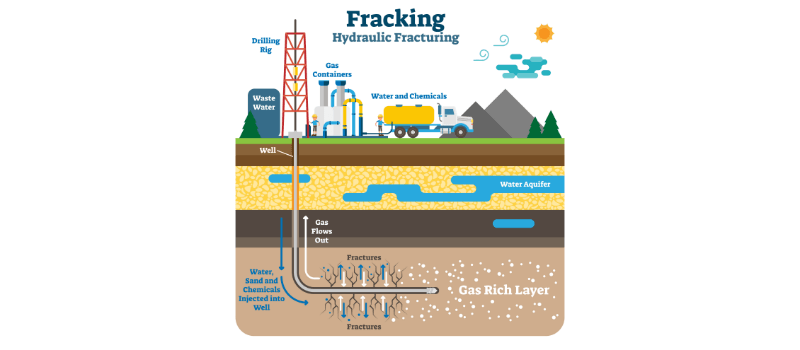

Well Stimulation and Completion Techniques

Well stimulation improves well productivity and flow efficiency.

Common Techniques

- Hydraulic fracturing

- Acidizing

- Perforation

- Gravel packing and sand control

- Multi-stage fracturing

- Intelligent completions

Conclusion:

Technique selection depends on reservoir type and formation characteristics.

Petroleum Reserves Classification and Estimation

Reserves estimation helps companies plan exploration and production strategies.

Reserve Categories

- Proved (1P) – High certainty

- Probable (2P) – Moderate certainty

- Possible (3P) – Low certainty

Estimation Methods

- Volumetric analysis

- Material balance

- Decline curve analysis

Conclusion:

Accurate reserve estimation is vital for investment and field development decisions.

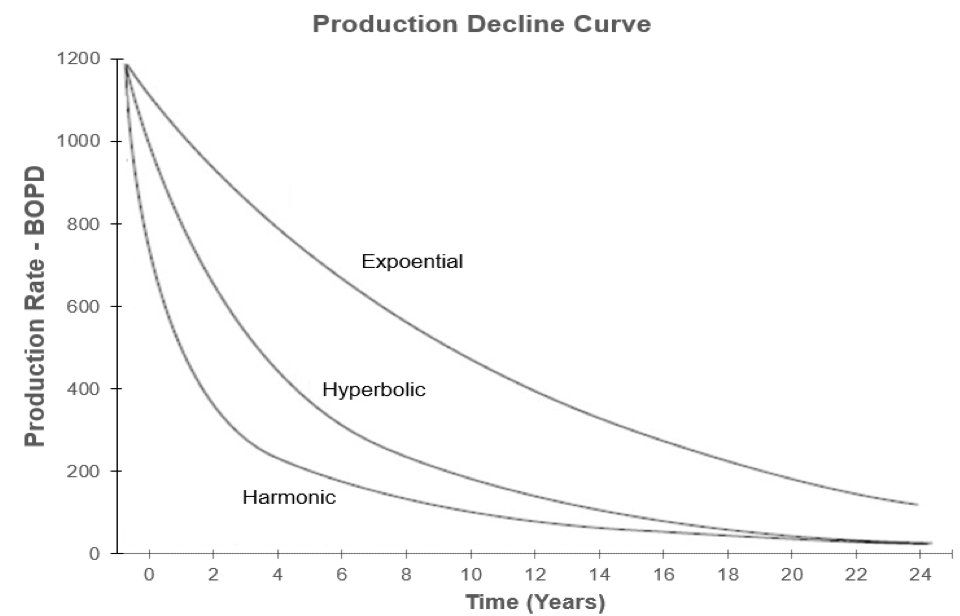

Production Forecasting and Decline Analysis

Production forecasting predicts future oil and gas output.

Forecasting Techniques

- Analytical

- Numerical (simulation-based)

- Empirical (historical data)

Decline Models

- Exponential

- Hyperbolic

- Harmonic

Conclusion:

These tools help evaluate field life and economic viability.

Sustainability and Renewable Energy in Petroleum Engineering

The industry is evolving toward lower-carbon and sustainable operations.

Sustainability Practices

- Carbon Capture and Storage (CCS)

- Emission reduction

- Water and waste management

Role of Renewables

- Solar and wind for field operations

- Biofuels as alternative energy sources

Conclusion:

Petroleum engineers play a key role in the energy transition.

Petroleum Product Quality Control and Specification

Petroleum products must meet strict quality standards.

Quality Control Tests

- Octane number (gasoline)

- Cetane number (diesel)

- Flash point

- Viscosity

Product Specifications

- Defined by industry bodies and regulators

- Environmental limits (e.g., sulfur content)

Conclusion:

Quality control ensures safety, efficiency, and regulatory compliance.

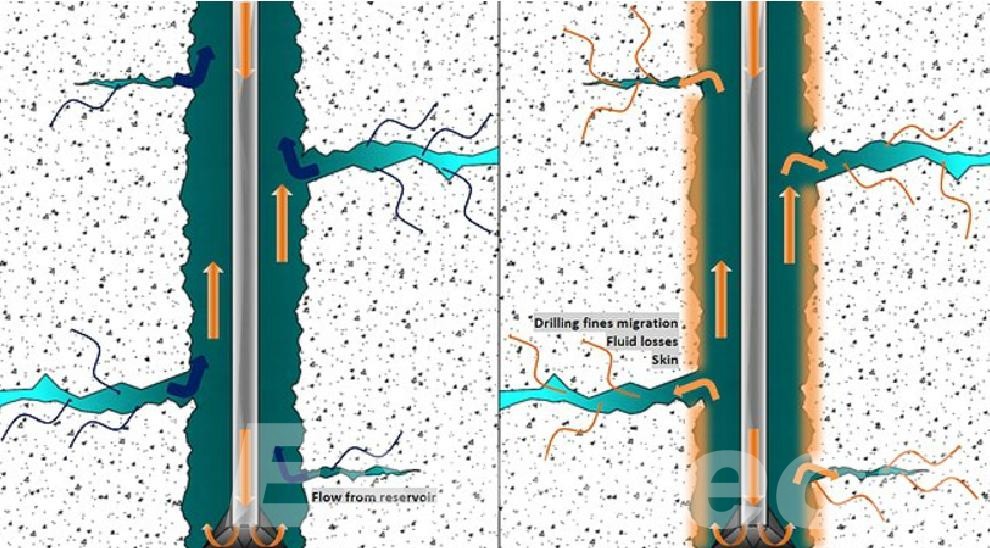

Well Intervention and Workover Techniques

Well productivity declines over time and requires maintenance.

Well Intervention

- Coiled tubing

- Snubbing

- Slickline operations

Workover Operations

- Tubing replacement

- Fishing operations

- Re-perforation

Conclusion:

Proper intervention extends well life and improves performance.

Petroleum Asset Management and Portfolio Optimization

Asset management focuses on maximizing value across the asset lifecycle.

Key Techniques

- Risk management

- Performance analysis

- Portfolio modeling

- Asset valuation

Conclusion:

Effective portfolio optimization improves returns and reduces operational risk.